Motion Kit Update here. I am now using Black Forest Motion’s Pine r controller, a far more satisfactory unit.

Finally, a three axis system working in Cambodia, controller and motors from the US, pan tilt designed by me here in Cambodia, manufacturing in the good old UK, slider from Thailand. A mammoth 8 month project. Heres how it unfolded.

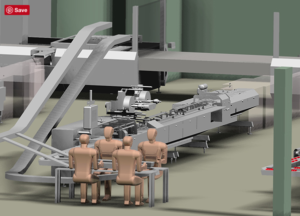

My work in the UK, concept design from mechanisms to full factory systems.

A quick note about me. I have given up a good job as a design engineer back in the UK to concentrate on photography here in Cambodia. It’s a beautiful place with great people, living ‘the dream’ some say. My work here is focused on the culture, non-commercial, so funds are limited. I don’t know why, but I’ve got myself hooked on this time-lapse. Perhaps it’s my background, being a design engineer, dealing with mechanical drives and bringing motion to my work, maybe it is the great work I am seeing out there on the internet, or just a way of extending my personal photographic limits.

I could have purchased a complete system, but knowing the ‘efficiency’ of the postal service here, I decided to do it piece meal. After a lot of research I decided on a 3 axis controller & motor from the US, which I could ship to the UK and have a friend bring to Cambodia for me, thus avoiding any ‘complications’ with the Khmer postal service, the rest I would sort out, easy, you may think…

So, first step. Order components from US (one motor in the original order as I wanted to have confidence prior

Digilife slider from Bangkok

to ordering the second two motors for pan tilt) and get slider from Thailand, a short trip across the border. I purchased a 1m ‘digilife’ slider for a very good price, the carriage running on bearings, fairly well designed for a Thai company. A bit of modification to the bearing spacers and I had a smooth slide rail. Next up, battery. Having been assured they exist in Bangkok, two days of searching only to reveal 5v batteries for mobiles. So again, due to my confidence in the Cambodian postal system, I had to rely on someone bringing a battery pack from the UK.

Delivery of the components from the US. Due to two errors with the order, shipping and relying on people to carry things from the UK, the whole order took 73 days to complete, frustrating. The Americans excel at blowing there trumpets and taking plaudits. When it go wrong however, some seem to lack a sense of responsibility. During my time as a design engineer the customer was always right..

Lets design 🙂 3D modeling.

Finally, a working system. The next step was to design the pan tilt units,, based on the motor supplied in the first shipment, great – its been my job designing mechanical machines and drives for nearly two decades. With the drawings ready, manufacturing here in Cambodia being non existent, the easiest thing to do was to get parts made in the UK by an old work colleague, good old British engineering. The parts  didn’t take long, and were brought to Asia by my brother in March this year. All went together well. The second order from the US, the motors, were delivered to the UK and brought by a friend. Finally a working three axis system.

didn’t take long, and were brought to Asia by my brother in March this year. All went together well. The second order from the US, the motors, were delivered to the UK and brought by a friend. Finally a working three axis system.

When used level, the pan unit bolts direct to the slider carriage giving a nice low centre of gravity. I’ll design out the ball head in favour of an adjustable wedge to keep things compact, all in good time. It was designed as a one off using traditional machining methods. If it were designed for selling I would have done things differently, reducing weight and using modern machining practices, and would have designed my own slider, but alas that technology is not here in Cambodia, the Kingdom of wonder.

Using the system.

My first planned project was to be the majestic temples of Angkor. However, I was to quickly learn that anything resembling more than a tourist camera requires special permission from the Apsara authority ($$$). So ironically, after waiting for so long to complete the project, the use of my slider was out. The Angkor project was completed to coincide with the completion of this website. The Angkor timelapse was not as quite as I intended as we have had bad sky conditions for any attempt at night shots, alond with restricted opening times. So it’s onwards with a project outside the Angkor park, the right time of year now.

I find myself either doing stationary clips now and putting a bit of movement in post, or possibly one or two axis, the slider often stays at home. My mode of transport is a 250 dirt-bike, so it’s good to travel light. With one axis, controller, battery, a 6D and a couple of lenses my kit bag is full. If my usage increases I’ll design out the ball head in favour of an adjustable wedge to reduce height offset from the rail. I’ve enjoyed making my own system. I know there is room for improvement. With commercial available systems there are some great innovations becoming available as things evolve. It’s all been a good learning curve which I have fitted around my photography tours and other projects.

Some timelapse projects here:

2 comments. Leave new

Awesome work mate. Which controller you are using to control the motors? would appreciate your help.

Cheers Harris. It’s DP’s NMX controller, works ok. Any thing else just ask.